MMOOKA

Portable laser welding spawarka laserowa 1500W welding equipment for meal weld fiber laser aluminum weld cnc machine

Portable laser welding spawarka laserowa 1500W welding equipment for meal weld fiber laser aluminum weld cnc machine

Couldn't load pickup availability

Cyrielle Wang

Email: export33@acctekcnc.com

WhatsApp: +86 15253151868

Portable laser welding spawarka laserowa 1500W welding equipment for meal

weld fiber laser aluminum weld cnc machine

Display and components of fiber laser welding machine

1) Simple and easy to operate, the weld is not deformed.

2) Laser output is stable, ensuring weld consistency.

3) High power density after laser focusing.

4) The weld seam is smooth and beautiful, the welding workpiece has no deformation, the welding is firm, and no subsequent grinding process is required, which saves time and cost.

5) 360 degree without dead angle micro soldering

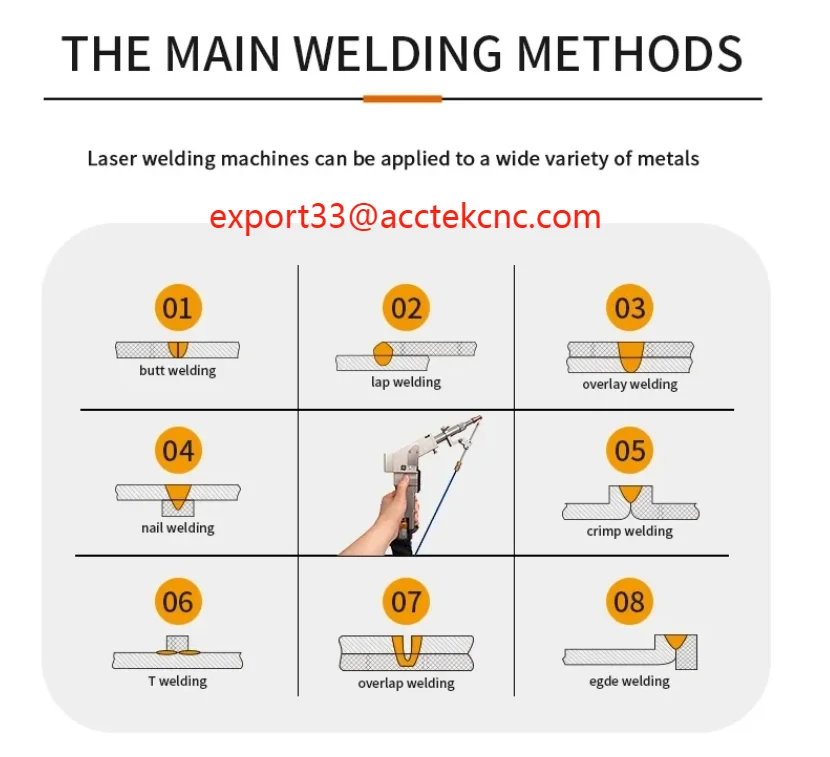

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned and used in the group welding of micro and small size workpieces for mass production. mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, butt welding, stack welding, sealing welding, etc., high aspect ratio, small weld width, small heat affected zone, small deformation, fast welding speed, no need to be processed after welding or simply processed.

6) Fast, easy to operate, labor saving Fast welding speed, 2-10 times faster than traditional welding, one machine can replace at least 2 welders a year.

7) Long life working, safer and more environmentally friendly laser welding is with low consumables for micro soldering.

Details of fiber laser welding machine

1. Fiber laser welding head:

The working mode can be freely switched according to different application scenarios, providing diversified solutions for users' different application needs. The product covers welding head/cleaning head and self-developed control system, and sets multiple safety alarms and active safety power and light off settings. It has the characteristics of high reliability and high stability. The product can be adapted to various brands of fiber lasers, optimized optical and water-cooled design makes the laser head can work stably for a long time under 2000W. Weight 0.7kg.

2. Fiber Laser Source

The third generation of single-module continuous fiber laser developed by Raycus has higher photoelectric conversion efficiency (>40%), better and more stable beam quality, and stronger anti-reflectivity. The optimized second generation transmission system is also introduced to ensure more stable and precise results in welding.

1. High photoelectric conversion rate

2. Maintenance-free operation

3. good quality of laser output

4. Strong anti-hyper-reflection capability

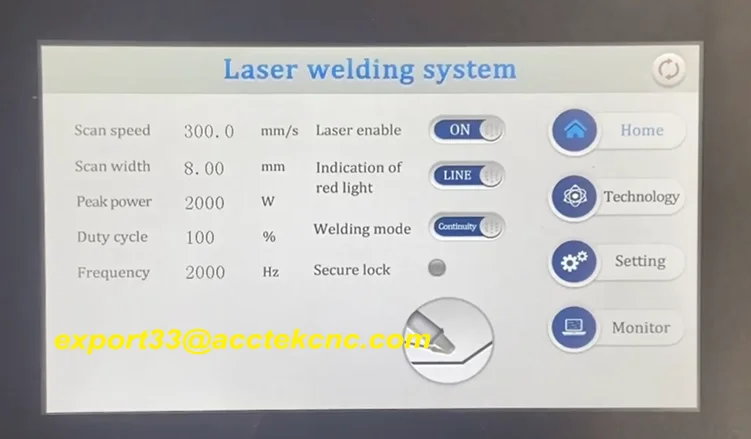

3. Contorl System

Humanized design operation panel, touch control by hand, complete functions, convenient for users to operate.

All parameters are visible, monitoring the whole machine status in a real time to avoid problems ahead of time,facilitate troubleshooting and problem solving to ensure the stable operation of the system

Supporting 8 kinds languages to meet more clients’ requirements.

Including welding/cleaning/cutting working modes, a dedicated laser source data monitoring page, technical info. can be set to try various of process effects.

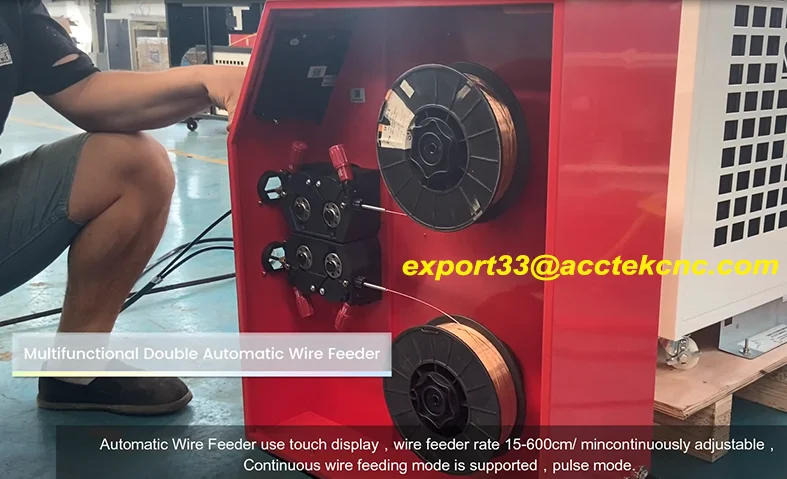

4. Double automatic welding wire :

Automatic Wire Feeder use touch display,wire feeder rate 15- 600cm/ mincontinuously adjustable,Continuous wire feeding mode is supported,pulse mode.

Parameters of fiber laser welding machine

Description |

Parameter |

Model |

AKH-1500/ AKH-2000/AKH-3000 |

Power |

1000W/ 1500W/ 2000W |

Range of adjustable power |

1-100% |

Laser wavelength |

1070nm |

Fiber length |

Standard 10m, maximum support 15m |

Way of working |

Continuous/modulation |

Speed range |

0-120mm/s |

Repeat precision |

±0.01mm |

Welding thickness |

Welding thickness |

Welding gap requirements |

≤0.5mm |

Cooling water |

Industrial therm ostatic water tank |

Working temperature |

15-35℃ |

Working humidity |

<70% no condensation |

Voltage |

380V |

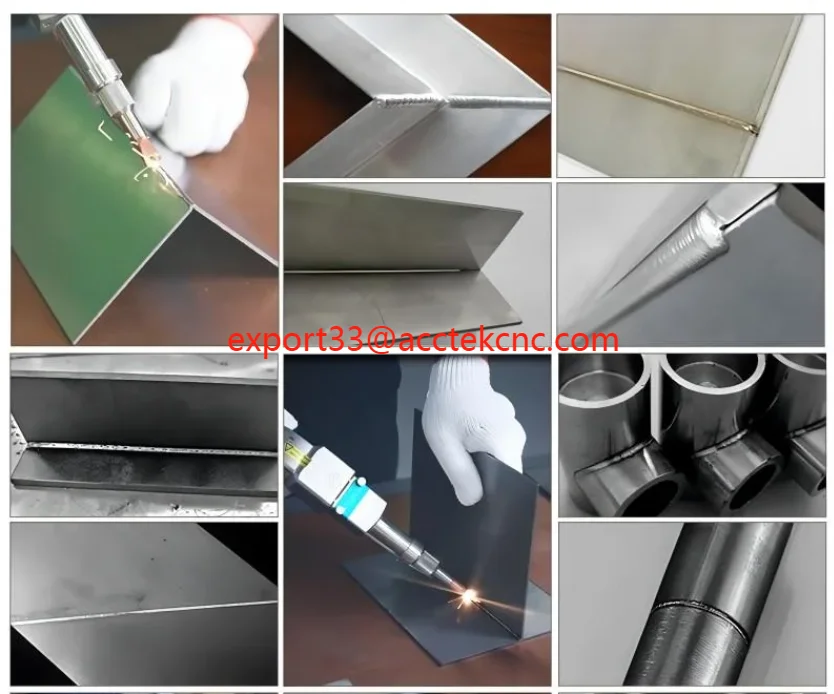

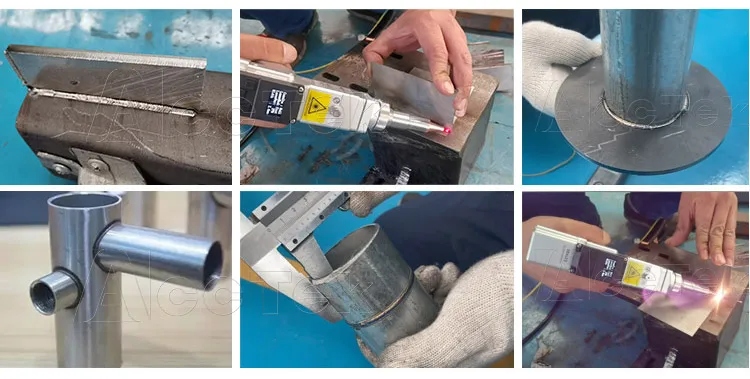

Samples of fiber laser welding machine

Applicable Material of Fiber Laser Welding Machine

Stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys, it can also be used for a variety of welding between different materials, such as: copper - brass, titanium - molybdenum, titanium - gold, nickel - copper and so on.

Applicable Industry of Fiber Laser Welding Machine

Kitchen cabinets, staircase elevator, shelf, oven, stainless steel door, window guardrail, distribution box, medical equipment, communications equipment, craft gifts, household and other industries.

Customer visit:

Training abroad:

Hope to see you in 2024 Exhibition !

Cyrielle Wang

Email: export33@acctekcnc.com

WhatsApp: +86 15253151868

Share

Collections

-

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion