MMOOKA

Pneumatic Ultrasonic Plastic Welder Spot Welding Machine 500W 35KHz Welder Equip

Pneumatic Ultrasonic Plastic Welder Spot Welding Machine 500W 35KHz Welder Equip

Couldn't load pickup availability

HZ-35K Ultrasonic Bonding Machine Manual

Function: Suitable for brassiere, underwear, swimwear, shoe uppers and other two-layer fabric bonding points to save threads, improve product quality and efficiency. Another is also widely used in clothing, clothing, shoes, toys, leather goods, handbags, embroidery, glasses and other industries such as ironing diamonds and plastic welding processing.

Note: The best workbench mat board with tiles (floor tiles, can not use a high degree of smooth floor tiles, will be slippery) or frosted glass as a mat board. Or with 2 cm thick stainless steel plate can also be, but the effect is not so good, because the metal plate absorbs heat quickly. Can not use a too thin metal plate to do the mat board.

Product Parameters:

|

|

Features:

1. Convenient Operation

2. Easy Maintenance

3. Higher Efficiency

4. Strong Applicability

Machine Shape Diagram

Portable Ultrasonic Bonding Machine

1 Power switch |

6 Start switch |

2 Amplitude meter |

7 Handle |

3 Carrying handle |

8 Vibrator |

4 Fusing time |

9 Die |

5 Detection switch |

Maintenance Guidance

Failure |

Cause |

Solution |

Output power is not enough |

|

|

Abnormal sound (screeching sound) |

|

|

The handle has a burnt smell or sparks |

|

|

Without ultrasonic output |

|

|

Handle hot (vibrator work will naturally generate heat, but can not be too high, generally in the 50 ℃ or so normal) |

|

|

Ammeter pointer is large |

|

|

Replace the new handle |

|

|

Precautions, Common Sense and Routine Maintenance

- The welding head should not work directly with metal objects.

- The output force of the welding head is different for different types of shapes and sizes

- The output wire cannot be pulled with excessive force.

- The current is normally between 0.3 and 0.6 A at no load.

- FM screw set current at 0.3-0.6A when locked, can not be twisted at will (to ensure that the current is in the minimum position)

- Detect whether the no-load current is between 0.3-0.6A before work every day.

- The handle must be hung on the workbench so that it works vertically.

- Do not play freely outside the working period, and take care of the equipment.

- The greater the hand force, the greater the output force of the welding head, and vice versa if the hand force is small.

- When loading or unloading the die head, two opening wrenches must be used at the same time, one on the die head and one on the vibrator (the above action can be carried out only when the plastic nut of the handle is twisted loose and taken away first).

- Before installing the die head, wipe the face of the vibrator and die head clean, the screws should be locked in the die head and then locked with the vibrator, usually also pay attention to whether it has loosened.

- Do not collide and twist the handle with hard objects, which will break the handle and twist the wire.

- Check regularly whether the fan is functioning properly.

- For long-time use, the handle is naturally hot, please use the air gun to blow cold or natural

Share

Collections

-

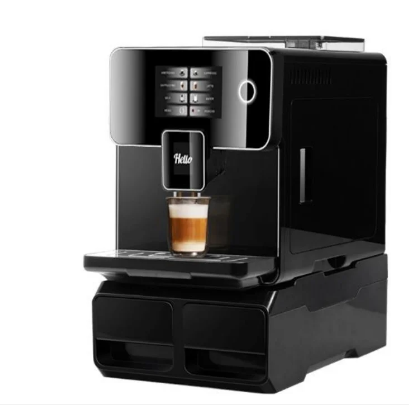

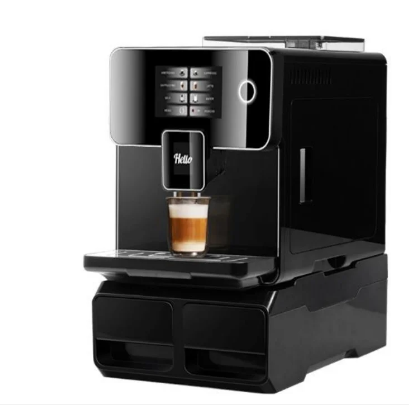

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion