MMOOKA

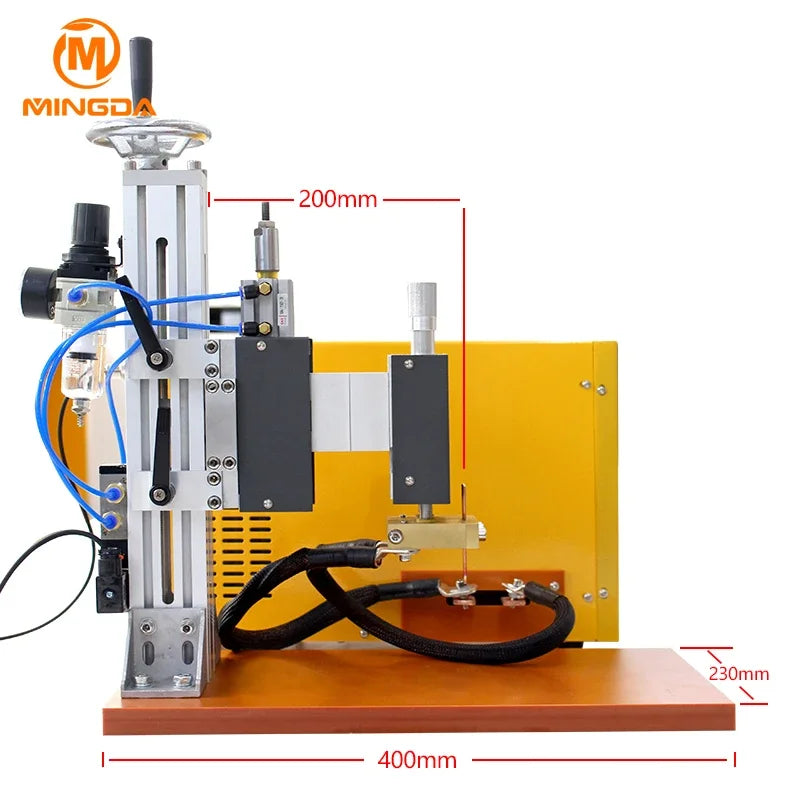

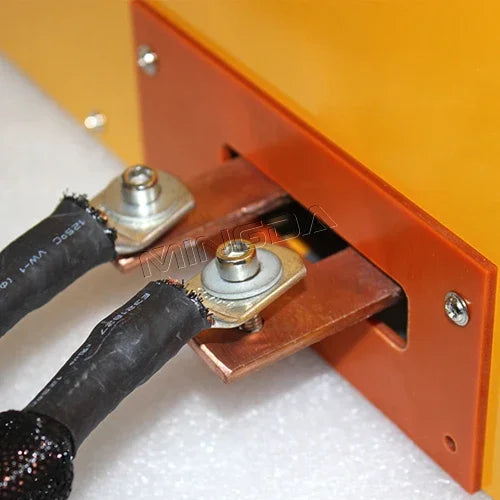

MINGDA Strong Secondary Max. Current Spot Welder For Batteries , MD-500 Welding Equipment Made In China

MINGDA Strong Secondary Max. Current Spot Welder For Batteries , MD-500 Welding Equipment Made In China

Couldn't load pickup availability

Main Technical Characteristics:

1) DC output. Welding current is pulsating DC (and waviness small), no AC shortcomings zero-crossing is not continuous heating the workpiece, heat concentration, improve the welding thermal efficiency, it's particularly suitable for nonferrous metal materials and some difficult welding materials, stable welding process, improved the welding quality significantly. Meanwhile, extended the electrode life.

2) High speed and high accuracy microprocessor (MCU) control, provides highly stable repeat welding, with current monitoring function.

3) Inverter with soft-switching technology, reduce the switching losses and electromagnetic interference.

With the fault diagnosis of abnormal currents, monitor overload, voltage overrun and alarm function.

4) Time wide range (0 - 9.9 ms), can be used for multi pulse application of complex welding process needs.

10 parameters stored welding specification, convenience for the various welding varieties to use.

5) 128 * 64 Chinese LCD display, and display a variety of content at the same time, graphical display of the current operating state, friendly interface, welding pulse graphics display function to improve the convenience of debugging observation.

6) Welding speed: fast start and high-speed polarity switching reduces the temperature so that the welding surfaces are clean and beautiful.

7) Polarity switching: suppression of asymmetric effects to make two uniform welding strength and prolong the service life of the electrodes.

8) Imported IBGT module full bridge control welding discharge, welding quality and speed of non conventional energy storage welding can be compared.

9) Double-pulse reduces welding spatter, effectively improve the weld quality.

10) Data storage using EEPROM, no battery life issues, each time you boot back to previous welding procedures.

Welding voltage locking techniques to prevent the network voltage fluctuations affect the welding current.

|

Parameter

|

|

|

|

|||

|

Maximum power transformer output

|

25KVA

|

|

|

|||

|

Secondary maximum welding current

|

6000A

|

|

|

|||

|

DC capacitor

|

6600uF

|

|

|

|||

|

Welding pulse number

|

9 sets of pulses

|

|

|

|||

|

Welding voltage

|

5V-330V adjustable, precision 0.5V

|

|

|

|||

|

Welding time

|

0.1ms-5.0ms adjustable,precision 0.1ms

|

|

|

|||

|

Welding mode

|

General / continuous

|

|

|

|||

|

Input frequency

|

AC 220V±10% 50Hz±2Hz

|

|

|

|||

|

Maximum operating pressure

|

6kg

|

|

|

|||

|

Machine weight

|

70kg

|

|

|

|||

|

Welding thickness

|

0.03mm~0.5mm multiple welding pieces

|

|

|

|||

|

Platform size

|

40*23cm,80*60cm

|

|

|

|||

Shenzhen MINGDA Technology Co., Ltd

We developed the production of series inverter DC resistance welding machines, applying the most advanced inverter technology and microelectronics technology, which is a precise resistance welding equipment, has features of precise control, process flexibility and energy saving, efficient, stable, easy to operate and so on.

Our company has a research and development team, with strong development and design capability, continue to develop new products to market.

We strictly in accordance with the modern enterprise management system of production, management, and pay high attention to the quality of products and services. All main components are used the world first-class products, such as Germany's Siemens, American IT company, the American microchip company, ATMEL company. High-quality components, advanced technology, modern management, to ensure the stable and reliable product performance. Our products are widely used in electronic connectors, electronic products, automotive, batteries, medical equipment, lighting and other industries.

We have rich experience to promote and export products to all over the world.

We have a professional team to manage our all wholesale international business.

Our business principle is"Excellent Quality;Best Service;Competitive Price".

Pre-sale services for MINGDA spot welders manufactures

1. Providing professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

4. Personal call or visit are warmly welcome.

Share

Collections

-

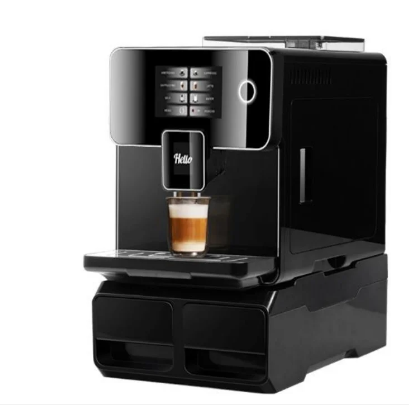

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion