MMOOKA

hot sale flex seaming machine hot sale hot air plastic cloth flex banner equipment

hot sale flex seaming machine hot sale hot air plastic cloth flex banner equipment

Couldn't load pickup availability

banner welder/Best selling intelligent banner welder machine/Automatic Hot air flex PVC PE banner welder with a free heater

Model:liw3000A

Intelligent banner welder machine

When picture size more than printer printing width, need to split the picture to some

part, after print out then weld them together. Usually use 502 glue to joint them by

hand, but this way is disadvantageous, like: slowly, after long time the glue is not

hard, the glue will dirty picture, work by hand hard to control the quality etc.

Our intelligent banner welder can resolve the problem successfully. Our machine no

need glue, use hot air to melt the material and joint them together; it can move

itself in work; with sensor in the welder nozzle, can control the work temperature

accurately; Work temperature, speed, and fan motor speed are adjustable; the body

made of steel, very strong; little dimension, 41*25*20cm, light weight, just 10.5kg,

can bring it to anywhere easily.

1. Application field

Use for welding PVC, PE banner and other material can be hot melt, like flex, PVC cloth etc.

2. Main technical details

Rated voltage: AC110-240V

Frequency: 50-60HZ

Power: 1000-3000W

Temperature scope: 0-500degree

Speed scope: 1-15m/min

Dimension: 41*25*20cm

Weight: 10.5kg

Splicing width: 2-5cm

3. Advantage

No need glue, use hot air to weld;

Temperature, speed, fan motor speed are adjustable;

Welder nozzle has a sensor, can make the true temperature accurately;

High welding quality.

4. Operation procedures

1). Before hemming or welding, leave 30-40mm wide overlap edge for connection the

two disjunct surface pieces, immobilize both ends of each disjunct pieces with something

such as stick belt or clamp.

2). Turn on the power, according to quality and thickness of the PVC banner, consider

the ground circumstance, set the proper termperature and speed, adjust the suitable

hot-air blowing rate, wait for machine hot up around 2 minutes.

3). Bring up the machine, place the rubber wheel at the end of the overlap edge.

4). Turn the handle to left down, insert the welder nozzle into the gap of two overlap

pieces, then the machine will moving and seaming automatic.

5). During welding, use the gripe to align the moving direction, let the upper piece

edge be in touch with the inner side of the welder nozzle.

6). After the machine go pass the overlap edge to the end, the two disjunct pieces

will be joined together, then turn the welder handle to right, it will stop moving.

7). Turn off the heater switch, wait the gun come to cold, then turn off the power

supply is ok.

8). Notice: To prolong the electrothermal heater, after work it is strongly advice that

cooling the heater at first, then turn off the power 5 minutes later. In case of the

power suddenly be off, should handle the welding gun away firstly, and close down

the temperature knob, nextly consider the problem of power supply.

9). To get better satisfied bonding effect, the ground of the overlap pieces should be

smoothly, hard and heat resistive. We suggest that the operator may do some more

test and practice using some samples of the pieces to get the suitable speed and

temperature and hot-air blowing rate before operate it for seaming formally.

Share

Collections

-

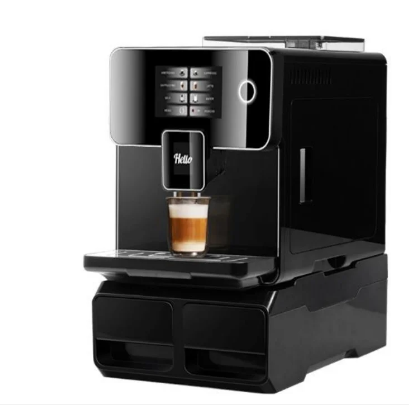

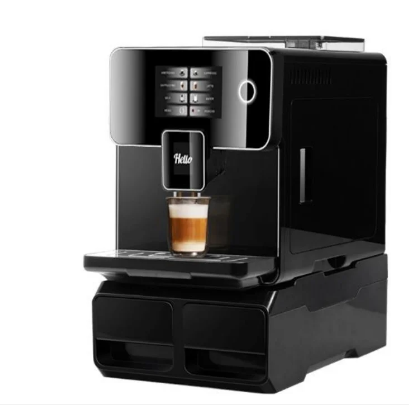

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion