1

/

of

6

MMOOKA

Enclosed Stainless Steel Orbital Pipe Welder Machine Welding Equipment

Enclosed Stainless Steel Orbital Pipe Welder Machine Welding Equipment

Regular price

$15,294.48 USD

Regular price

$19,118.10 USD

Sale price

$15,294.48 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Products Description

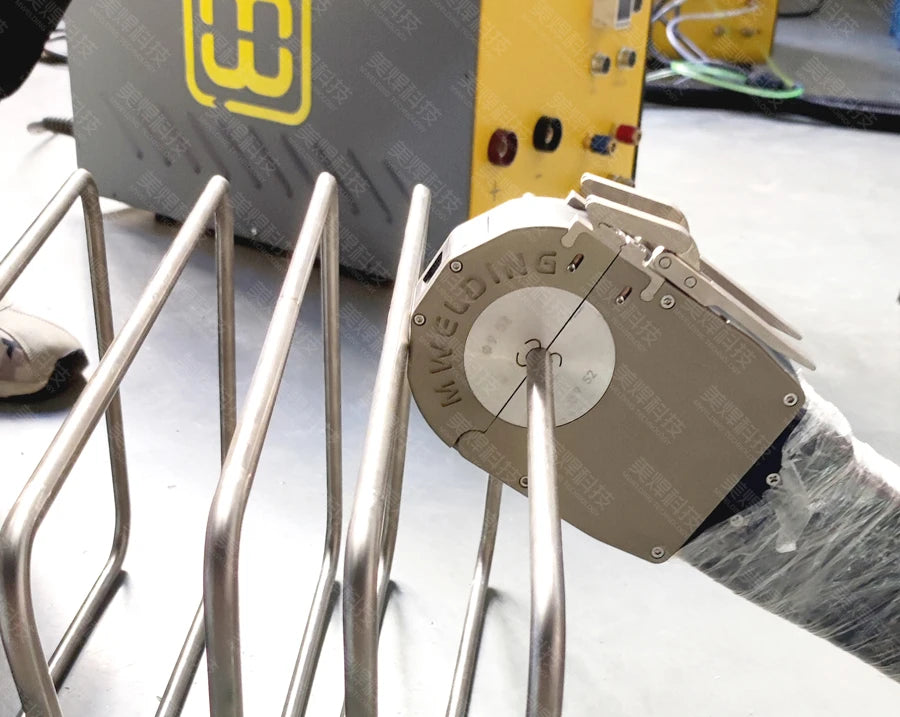

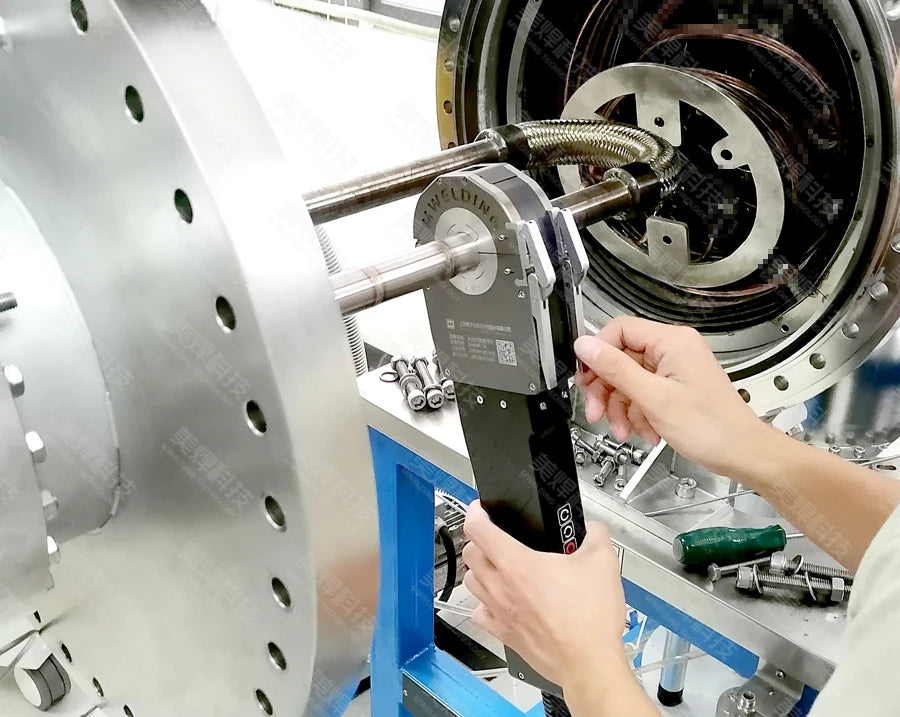

Closed Orbital Welder

Closed Orbital Weld Heads

All closed orbital weld heads of the ORBITAL-WELDING series are made from strong, durable materials of the finest quality and are characterized by their unique water cooling system.

The appropriate high-grade, functional and long-lasting clamping inserts are lasting longer than the inserts of many competitors.

The inserts are available in small and wide designs and are easily and quickly insertable into the weld heads.

The appropriate high-grade, functional and long-lasting clamping inserts are lasting longer than the inserts of many competitors.

The inserts are available in small and wide designs and are easily and quickly insertable into the weld heads.

Integrated Control Power Supply MWA-200

Our power supplies have been designed to be user-friendly and intuitive. Our step-by-step design allows, even beginners, to easily generate programs after only a short learning period, while very advanced functions are available to advanced users looking to customize their programs. Particular attention has been paid to using as many as possible standard industrial components for their reliability and availability. The facilitated access to parts makes our power sources robust and easy to maintain.

The combination of an easy-to-use and sturdy package allows you to be competitive and makes this range the best choice for all your current or future projects.

The combination of an easy-to-use and sturdy package allows you to be competitive and makes this range the best choice for all your current or future projects.

Product Details

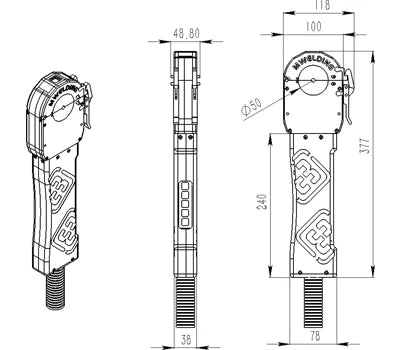

Closed welder head

1.The whole body of the welding torch is water-cooled, which improves the temporary load rate of the welding torch,prolongs the life of welding torch, and does not heat up for a long time.

2.There are 4 channels of argon protection inside the welding torch chamber to improve the quality of the welding seam and make the welding seam more beautiful;

3.With the speed measurement function with feedback, the rotation of of the welding torch is more accurate and stable, and the angle of the welding seam is monitored in real-time;

4.With expert parameters,only need to input the diameter and wall-thickness of the pipe fittings, the welding parameters can be automatically generated,and the welding can be performed;

5.The full welding torch adopts all imported materials, is lightweight one-button operation, convenient, and easy to learn;

6.The welding gun adopts a flexible fixture, which can be fine-tuned according to the tolerance range of pipe fittings so that the welding gun can firmly lock the pipe fittings.

2.There are 4 channels of argon protection inside the welding torch chamber to improve the quality of the welding seam and make the welding seam more beautiful;

3.With the speed measurement function with feedback, the rotation of of the welding torch is more accurate and stable, and the angle of the welding seam is monitored in real-time;

4.With expert parameters,only need to input the diameter and wall-thickness of the pipe fittings, the welding parameters can be automatically generated,and the welding can be performed;

5.The full welding torch adopts all imported materials, is lightweight one-button operation, convenient, and easy to learn;

6.The welding gun adopts a flexible fixture, which can be fine-tuned according to the tolerance range of pipe fittings so that the welding gun can firmly lock the pipe fittings.

Integrated Control Power Supply

1. MWA-200 programmable welding power source consists of the control system, inverter core, cooling water tank, etc.

2. The equipment adopts a German Siemens PLC control system, EWM welding movement, Swiss Maxon motor,Omron relay, and other imported configurations. Precise control of various input and output signals.

3. Using touch man-machine interface, fast switching between Chinese and English interfaces, color 10-inch touch screen, graphic and step interface design, easy to operate and easy to learn and meet the requirements of different venues.

4. With functions such as parameter saving/printing, it can be operated with basic welding skills.

5. Real-time monitoring of welding parameters such as current, voltage, and speed during the welding process to ensure the safety and efficiency of the welding process.6.A complete set of welding control power supply, small size , lightweight(only 18 kg), convenient for on-site mobile high-altitude welding operations.

2. The equipment adopts a German Siemens PLC control system, EWM welding movement, Swiss Maxon motor,Omron relay, and other imported configurations. Precise control of various input and output signals.

3. Using touch man-machine interface, fast switching between Chinese and English interfaces, color 10-inch touch screen, graphic and step interface design, easy to operate and easy to learn and meet the requirements of different venues.

4. With functions such as parameter saving/printing, it can be operated with basic welding skills.

5. Real-time monitoring of welding parameters such as current, voltage, and speed during the welding process to ensure the safety and efficiency of the welding process.6.A complete set of welding control power supply, small size , lightweight(only 18 kg), convenient for on-site mobile high-altitude welding operations.

Production Spefication

|

Model

|

MWF-12

|

MWF-18

|

MWF-40

|

MWF-80

|

MWF-120

|

MWF-168

|

|

Applicable

diameter

|

Φ4.0-12.7

|

Φ4.0-17.1

|

Φ6.35-38.1

|

Φ19.05-76.2

|

Φ38.1-114.3

|

Φ50.8-168

|

|

Applicable

wall thickness(mm)

|

≤1.0

|

≤1.0

|

≤2.5

|

≤2.5

|

≤2.5

|

|

|

Protective gas

|

Argon

|

Argon

|

Argon

|

Argon

|

Argon

|

Argon

|

|

Cooling method

|

circular

water-

cooling

system

|

circular

water-

cooling

system

|

circular

water-

cooling

system

|

circular

water-

cooling

system

|

circular

water-

cooling

system

|

circular

water- cooling system |

|

Tungsten diameter

|

1.6

|

1.6

|

1.6/2.4

|

1.6/2.4

|

1.6/2.4

|

1.6/2.4

|

|

Weight(kg)

|

1.0

|

1.5

|

2.5

|

3.0

|

6.0

|

10.0

|

On SIte

Company Profile

Henan E-work Industrial Equipment Co., Ltd. is a professional company dedicated to the R&D, production and sales of piping tools and solutions to related pipeline problems. In line with the business tenet of "piping solutions expert" and the mission of "make work easy and efficient", we have independently developed and produced a series of products that customers love. Our product series mainly include pipe cutters, pipe scrapers, pipe squeezers, pipe welders, pipe benders, pipe threading machines, pipe cleaning machines, and pipe cutting beveling machines. These products are widely used for water pipelines, fire-fighting pipelines, gas pipelines, chemical pipelines, and petroleum pipelines. Our company not only has a professional and skilled workforce but also has established a complete and complete quality management system. We are committed to providing customers with world-class products and look forward to sincere and friendly cooperation with our customers to have a good business together.

FAQ

1. who are we?

We are based in Henan, China, start from 2013,sell to Domestic Market(30.00%),North America(10.00%),South Asia(8.00%),Mid East(8.00%),Southeast Asia(7.00%),Eastern Asia(6.00%),South America(5.00%),Africa(5.00%),Western Europe(5.00%),Eastern Europe(5.00%),Northern Europe(4.00%),Southern Europe(4.00%),Oceania(3.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

pipe cutting machine,pipe beveling machine,pipe bending machine,pipe threading machine,pipe welding machine

4. why should you buy from us not from other suppliers?

We are a manufacturer of pipe cutting beveling machines, pipe threader, pipe bender, HDPE pipe tool and related machine. Our company is dedicated to the R&D, production, sales of piping machines. If you need any piping solutions please directly contact us.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDU,Express Delivery,DAF;

Accepted Payment Currency:USD,EUR,GBP,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

We are based in Henan, China, start from 2013,sell to Domestic Market(30.00%),North America(10.00%),South Asia(8.00%),Mid East(8.00%),Southeast Asia(7.00%),Eastern Asia(6.00%),South America(5.00%),Africa(5.00%),Western Europe(5.00%),Eastern Europe(5.00%),Northern Europe(4.00%),Southern Europe(4.00%),Oceania(3.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

pipe cutting machine,pipe beveling machine,pipe bending machine,pipe threading machine,pipe welding machine

4. why should you buy from us not from other suppliers?

We are a manufacturer of pipe cutting beveling machines, pipe threader, pipe bender, HDPE pipe tool and related machine. Our company is dedicated to the R&D, production, sales of piping machines. If you need any piping solutions please directly contact us.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDU,Express Delivery,DAF;

Accepted Payment Currency:USD,EUR,GBP,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

Share

Collections

-

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion